Supply Shine

Digital Torque Wrench SN-030CN

Digital Torque Wrench SN-030CN

Couldn't load pickup availability

1、 Product positioning: Precise control solution for medium torque scenarios

SN-030CN focuses on conventional torque operation scenarios such as automotive maintenance, mechanical assembly, and equipment maintenance. With a balanced weight of 1.6kg and a reasonable total length design of 53cm, it balances operational efficiency and torque accuracy, solving the pain points of traditional wrenches such as torque ambiguity and poor adaptability, and supporting standardized assembly and maintenance processes.

2、 Basic parameter table

Project Details Description

Model SN-030CN

Weight 1.6kg (balanced operation force and durability, not tiring after long-term use)

Dimensions 53 × 13 × 7cm (suitable for regular workspace, flexible operation)

3、 Structure and Function Analysis

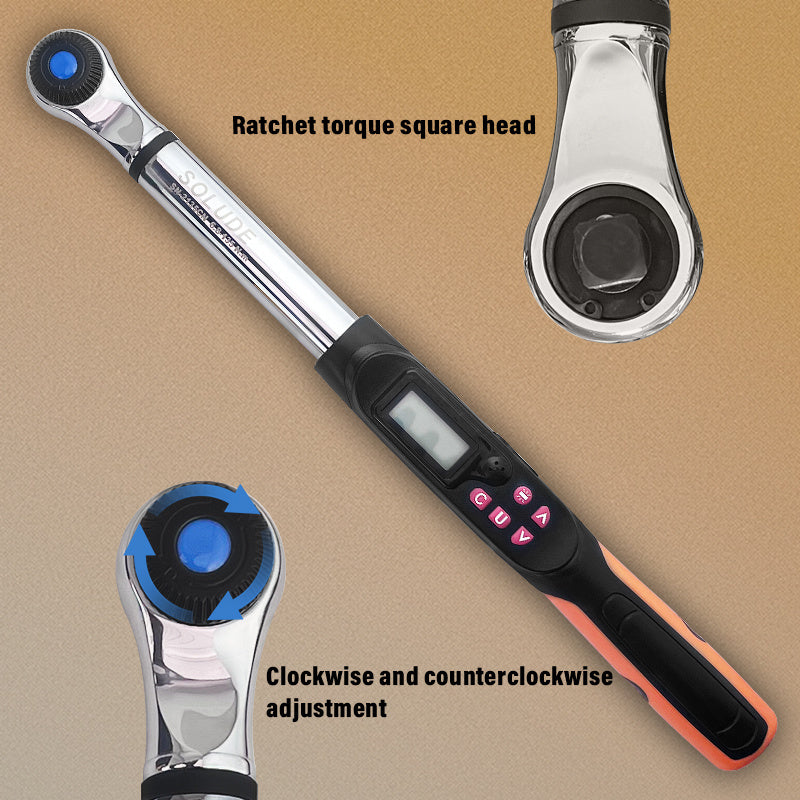

Head design:

Interchangeable ratchet head: compatible with open head, plum blossom head, and movable head (to be purchased separately), covering multiple types of bolts to enhance scene adaptability; The ratchet mechanism is smooth and the forward/reverse switching is efficient.

Central core area:

High definition LCD display screen: Real time display of torque values, units, and working modes, clear and visible in low light environments, bidding farewell to "blind twisting".

Multi functional buttons: support mode switching (peak/tracking), unit conversion, torque setting, data storage/clearing, simple operation logic (refer to the universal interaction design of digital wrenches).

Sound and light alarm system: When the set torque is reached, a buzzing sound and synchronized light prompts to enforce standardized operation and avoid over twisting/under twisting.

Controller optimization:

Dual material anti slip grip: wrapped in engineering plastic and rubber, with an ergonomic curved surface that fits the palm, reducing vibration transmission and operational fatigue; Anti slip texture enhances grip stability.

4、 Core functional highlights

High precision torque control:

Torque accuracy: clockwise ± 1%, counterclockwise ± 1.5% (within full range), ensuring that the tightening torque strictly meets the standard and avoiding the risk of structural failure.

Dual mode homework:

Peak mode: Record the maximum torque value during the tightening process for later review (such as equipment acceptance).

Tracking mode: Real time display of dynamic torque changes, suitable for monitoring scenarios such as debugging and maintenance.

Multi unit adaptation:

Supports free switching between N · m, ft · lb, in · lb, and kg · m, covering metric/imperial standards and adapting to torque specifications from multiple industries.

Data management:

Built in storage module, capable of recording multiple sets of torque data; Combined with communication expansion (same brand product logic), support data export and traceability, and assist in quality control.

Durability guarantee:

The main body is made of chromium vanadium alloy steel, which is impact resistant and corrosion-resistant; The internal sensors have undergone rigorous calibration, resulting in low precision degradation over long-term use.

5、 Typical application scenarios

Car maintenance: torque calibration of tire bolts, engine accessories, and chassis screws (to ensure driving safety).

Mechanical assembly: Precision assembly of equipment such as pumps, valves, motors, and conveyors to improve operational stability.

Maintenance of construction machinery: Tighten screws of excavators, loaders and other equipment (to cope with vibration conditions).

High end home installation: fastening of cabinet hardware, fitness equipment, and smart home appliances (balancing precision and aesthetics).

6、 Usage and maintenance suggestions

First use:

Refer to the instruction manual to complete the initial calibration, set the torque value, unit, and working mode (such as preset mode for batch tightening).

Daily maintenance:

Regularly clean the oil stains on the head and handle, check the battery level (replace it in a timely manner if it is low to avoid data errors).

After long-term idle, it is recommended to calibrate once a year (to ensure stable accuracy).

Condition avoidance:

Avoid working in environments with extreme high temperatures (>60 ℃), humidity (>90%), and dust for extended periods of time. Wear protective covers in special situations.

Share